Wydaje się, że budowa stacji energetycznej według określonych i sprawdzonych schematów nie powinna wiązać się z żadnymi nieprzewidzianymi sytuacjami. Praktyka jednak pokazuje, że bywa z tym różnie. W tym artykule wskazujemy kilka najczęstszych trudności, z którymi borykają się kierownicy budów w sektorze energetycznym. Zastanawiamy się, czy można ich uniknąć oraz podpowiadamy, jak rozwiązać problem, gdy się już pojawi.

Free consultationTable of contents:

- Why, despite good preparation, the plan does not always succeed?

- Time pressure and underestimation of needs are the most serious challenges

- Delivery accidents

- Disparities between projects and contractors

- Inconsistency in class and power of equipment

- Challenges and technical difficulties in the power sector - summary

Projects are approved, orders are placed, and delivery dates are arranged. Everything is perfectly organised and ready to go. The professionals are assembled and ready to work, so the team begins the operations. In an ideal world, everything goes as planned, and construction is completed or even ahead of schedule. Everyone shakes hands, thanking each other for their cooperation. A moment to breathe, and the next project can begin.

However, the reality is that a perfect world does not exist. Managers with many years of experience will confirm that construction proceeding without any difficulties along the way is a reality only in our deepest dreams. And on paper. Every project is fraught with the risk of various inconveniences and hindrances – and the bigger it is, the more acutely these obstacles are felt. As long as it comes to face the trifles that are easy to manage, there is no problem. However, it is not uncommon to encounter situations that are not easy to solve here and now, despite excellent preparation for the job.

Why, despite good preparation, the plan does not always succeed?

It is a simple fact that everyone knows that meticulous planning of every aspect of a project, including seemingly trivial details, is the foundation for a smooth and successful implementation. In practice, things are not as straightforward as they seem. Anyone who works in the energy industry knows this.

The starting point is always assumptions, designs, arrangements and an action plan. However, even the most carefully prepared plan can fall apart during implementation. While it may seem that such cases are primarily the result of oversights, the reality is that the causes can be many. Some of the reasons are surprising and unexpected, even to those who have worked in the industry for a very long time.

The energy sector is very demanding. Above all, the implementation of a construction plan requires careful planning of all components, excellent coordination between all specialists involved in the work, and a quick and accurate response in crisis. The human factor is often the most complex issue. This is not due to a lack of commitment to one's work.

Time pressure, poor communication at various levels, and accidents of chance can all lead to difficulties and delays, even when the best preparation for a project has been made.

We have already successfully completed dozens of substation projects, so we are well-versed in the challenges of the power industry. We have also solved numerous problems that arose along the way. We are sharing our experience and insights on the matter

Time pressure and underestimation of needs are the most serious challenges

The tender is won, so it's time to get ready for work. It is not uncommon for difficulties to arise at this stage, often due to an underestimation of the project and its needs. However, this is not usually the result of negligence. It is more often the result of the harsh realities of the situation. At this stage, it is realistic to assume that the documentation for these needs will include assumptions, requirements and standards. However, there is no strictly complete technical documentation yet.

Once the tender is won, it is time to create a detailed plan for a specific station. This is when the first difficulties arise. It is not uncommon for the assumptions in the tender documentation to differ from the real needs of a specific project.

These are the main reasons for change:

- change of planned equipment,

- investor's requirements,

- field conditions,

- changes in design assumptions.

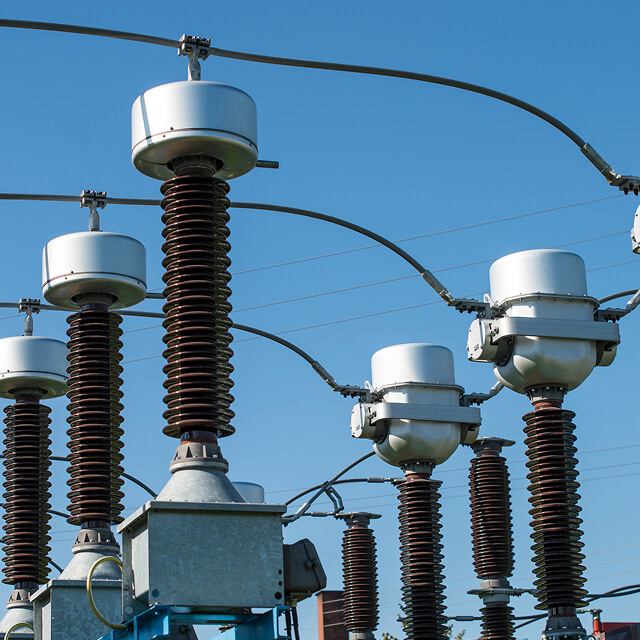

Firstly, we must verify that the arrester equipment has been chosen correctly, and that the other elements that make up the substation construction have been chosen correctly. However, another problem arises: time pressure. The deadline for implementation is already flowing, so you have to go back to the beginning and confront the data in the documentation with real needs.

The result is that… the process takes longer because a new offer must be created and sent to the investor for approval. Corrections to the project will inevitably extend the implementation timeline. However, as long as the inaccuracies can be caught before the order for various elements is placed, the problem will not be so acutely felt. It is therefore essential to work with trusted partners. At Protektel, we ensure that your order is fully aligned with your needs at the ordering stage. Our many years of experience have sensitized us to this issue.

The diversity of projects is a significant cause of underestimating needs and ordering the wrong parts. This raises another challenge: in addition to slippage in project implementation time, there is also the financial aspect. If you underestimate project assumptions, the budget planned for implementation will be far too small. Furthermore, you must factor in penalties for delays in implementation.

Delivery accidents

One further challenge that can impede the timely and efficient execution of a project is the occurrence of delivery accidents. A delay in the delivery of parts necessary for the next stage of the project, or a situation where it turns out that some of the parts are damaged for some reason, is another major problem. It will result in a slip in the project's completion time. Again, there is a lot of time pressure, and we must accept that random situations are beyond our control.

The most common contingencies are:

- turbulence in the supply chain of components for equipment production,

- transportation problems,

- production capacity of suppliers.

For example, the production process for high-voltage transformers takes up to six months. Ordering apparatuses much earlier is the only way to avoid a situation where something goes wrong. You can rest assured that we can store your ordered products in our warehouse, eliminating any logistical and storage challenges. Such a move will undoubtedly save you from a costly mistake.

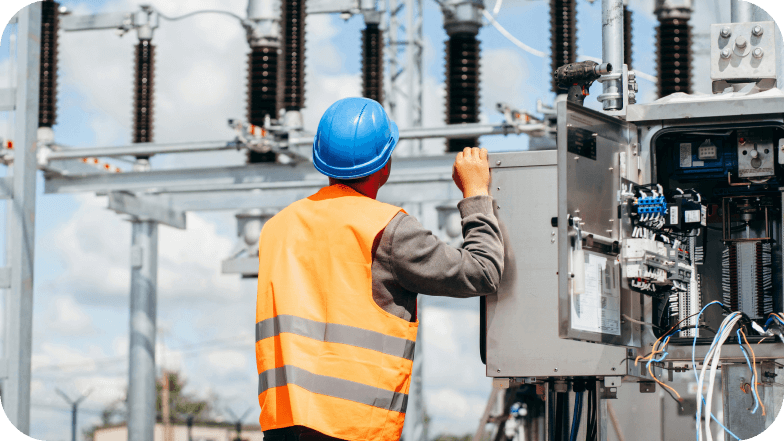

Disparities between projects and contractors

It is as important to coordinate the work of specialists from different sectors as it is to ensure that the components that make up the resulting station are fit for purpose. Discrepancies between the design and how the contractor sees it can lead to problems, such as an incorrectly drilled hole in a pole or the need to make changes to the structure, mounting or fitting of fixtures during the construction of the facility.

It happens that:

- the designer made a design, but it turns out that you need to change the supplier of equipment,

- the designer took into account individual parameters, but conditions on the facility force a change,

- the designer did not take into account or did not have all the data or assumptions of the project.

In such situations, it may seem that there is no solution. However, we always find a way to minimize potential delays and additional costs. One solution is to put in an adapter or modify the fixture to match the components while doing the work according to the art.

We also offer technical advice beyond the apparatuses we offer. In the case of a reverse-mounted arrester, we will tell you how to remount it without replacing the entire component. This avoids any risk of damage or loss of warranty. We are open to the needs of our partners and will always find the optimal solution for each situation.

Inconsistency in class and power of equipment

The order has been placed and is ready to be installed as soon as the stage arrives at the construction site. Our experience shows that there have been instances where, just before installation, discrepancies in the class, accuracy or power of the transformers have been identified. These discrepancies have often been caused by failure to meet design conditions or incorrect assumptions.

The most common difficulties that arise are related to:

- changes in demand on the part of the investor,

- changes in the requirements of the distribution company,

- general modification of the project.

In some cases, the safe use of apparatuses with underestimated power can be solved in various ways, requiring our involvement. The first solution is to make additional calculations. The apparatuses have a larger tolerance than specified by the manufacturer, which in some cases can save the situation and make it possible to use them. However, if this is not possible, the second solution is to make the necessary modifications to the secondary circuit of the transformer.

Challenges and technical difficulties in the power sector - summary

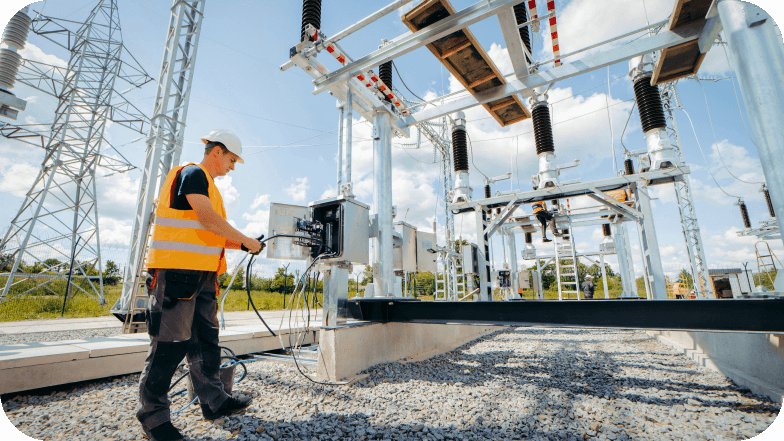

It is often assumed that newcomers to the industry face the greatest challenges. However, experience shows that various obstacles can arise at any time, even to those who think they know the power sector inside out. After all, it is impossible to predict everything, let alone prepare for it. While careful design is key, it is important to be prepared for random situations. However, you can rest assured that you will receive support with any problem that arises. Our energy specialists are on hand to provide support at every stage of the project, from planning to implementation, acceptance and legal support. We value the role of project managers and understand the responsibility and demands of their work.

Are you about to embark on a project and want to ensure everything goes according to plan, with a quick and effective response in case of unforeseen events? Contact us and let us know what you need. We have already participated in dozens of substation construction projects and are ready to support you with our experience. Book a no-obligation consultation today. When you work with Protektel, you gain a guarantee of a solid and reliable product, as well as support at every step of the project.