PROXAR® surge arresters, manufactured in Poland, meet the requirements of the IEEE C62.11-2020 standard although they are designed according to the European standard IEC 60099-4:2014. We explain what are the differences in interpretation between these standards and how exactly they relate to Protektel surge arresters.

Free consultationTable of contents:

We also export our PROXAR® surge arresters to countries such as Peru, Ecuador, and Brazil. This would not be possible if our devices did not comply with the IEEE C62.11-2020 standard. In practice, we have found that PROXAR® surge arresters exceed the requirements of this standard. Find out about this topic.

Table of differences between IEC 60099-4:2014 and IEEE C62.11-2020 standards

The degree of harmonisation between IEC 60099-4:2014 and IEEE C62.11-2020 is 80% today. The remaining 20% of the requirements relate mainly to the nomenclature used, but this also applies to the environmental conditions of surge arresters in specific applications. We describe this in the next section

The following table shows the differences between the requirements of IEC 60099-4:2014 and IEEE C62.11-2020.

| Aspect | IEC 60099-4:2014 | IEEE Std C62.11-2020 |

| Standard Organization | International Electrotechnical Commission (IEC) | Institute of Electrical and Electronics Engineers (IEEE) |

| Scope | General guidance and test procedures for surge arresters in AC systems, including both station-type and line-type | Specific requirements and testing procedures for metal-oxide surge arresters used in power systems |

| Application | Surge arresters for various applications, including station and line protection in AC systems | Surge arresters used in power systems, with a focus on metal-oxide surge arresters |

| Types of Surge Arresters Covered | Station-type and line-type surge arresters | Metal-oxide surge arresters |

| Design Criteria | Provides design criteria and test procedures for surge arresters without specifying the technology used | Focuses specifically on metal-oxide surge arresters, providing detailed design and testing requirements for this technology |

| Voltage Ratings | Guides surge arresters with various voltage ratings | Focuses on metal-oxide surge arresters used in medium-voltage and high-voltage applications |

| Testing Procedures | Specifies testing procedures for both station and line surge arresters, covering aspects like energy handling capacity, residual voltage, and more | Concentrates on testing procedures specific to metal-oxide surge arresters, including electrical, mechanical, and environmental tests |

| Energy Handling Capacity | Provides tests and criteria for energy capability and energy stress tests | Provides specific testing procedures to evaluate the energy handling capacity of metal-oxide surge arresters |

| Residual Voltage Testing | Includes testing for residual voltage after discharge events | Contains testing for residual voltage and protective margin of metal-oxide surge arresters |

| Temporary Overvoltage Tests | Testing procedures may vary based on surge arrester type | This may include testing for temporary overvoltage withstand capability |

| Pressure Relief Testing | This may include pressure relief testing, especially for station-type surge arresters | This may include testing related to pressure relief for metal-oxide surge arresters |

| Contamination Tests | This may include tests for contamination withstand | This may include testing for contamination in specific environments |

| International vs. American Standard | An international standard developed by the International Electrotechnical Commission | Developed by the Institute of Electrical and Electronics Engineers and follows American standards |

| Latest Version (as of September 2021) | IEC 60099-4:2014 | IEEE Std C62.11-2020 |

What are the reasons for the differences between the IEC and IEEE standards?

The main differences between IEC 60099-4:2014 and IEEE C62.11-2020 arise from the different approaches to the installation conditions of surge arresters, resulting from the characteristics of the power system and the influence of environmental conditions.

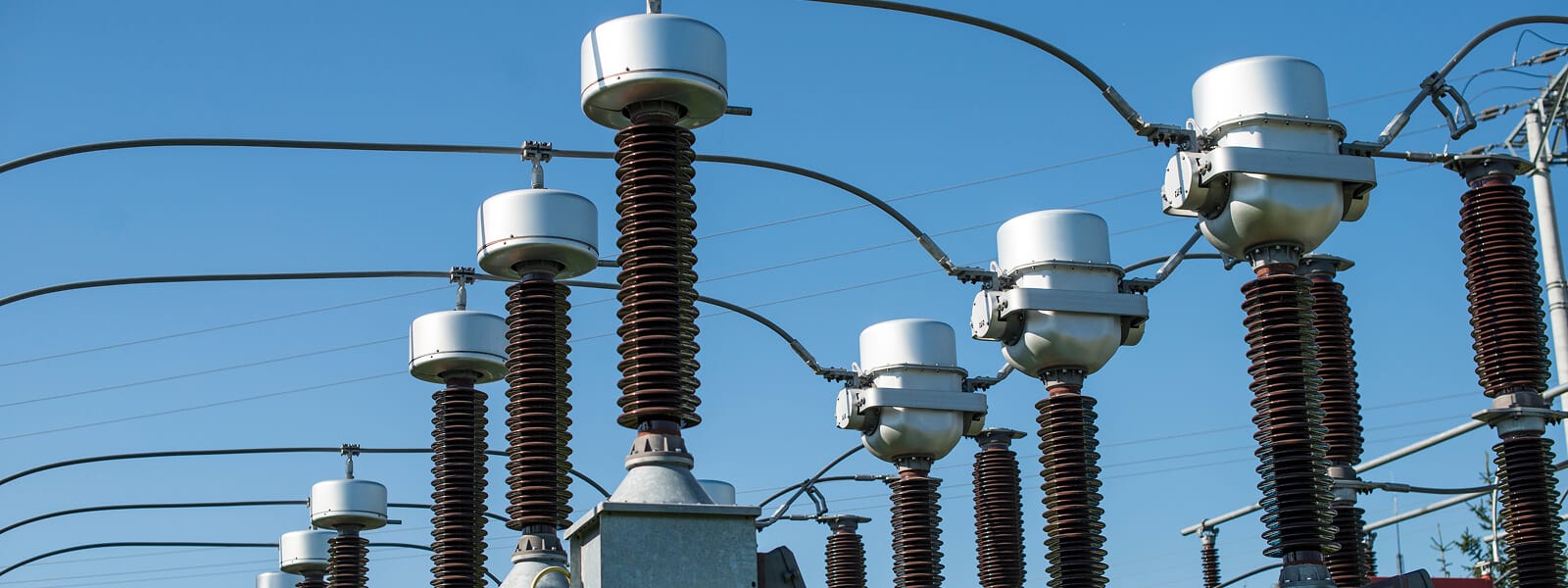

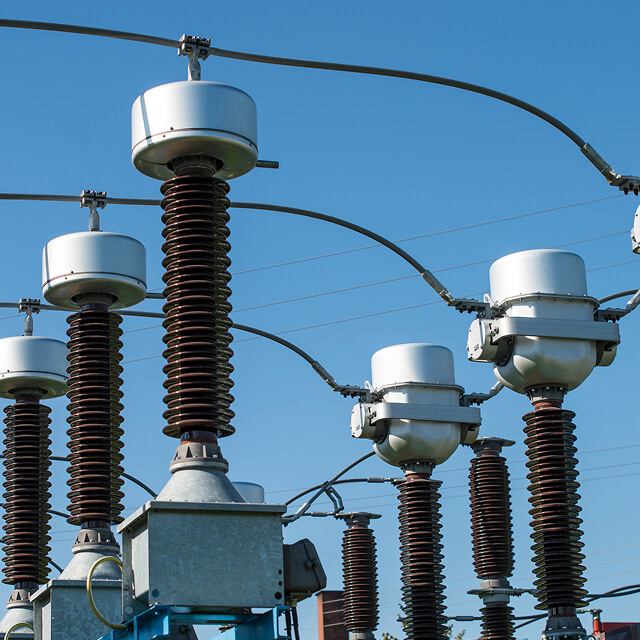

In Europe, such devices are preliminarily designed, manufactured, and used to protect substations and line power facilities. Therefore, such surge arresters, when designed for mounting on load-bearing elements, have a mechanically robust structure and solid fixings. This requires the use of additional material, which increases the device's weight and manufacturing costs of the device.

Meanwhile, in the Americas, due to the much greater distances between substations, surge arresters are mainly used to protect transmission line insulators and so-called compact lines. This results in a different way of installing them, which does not require such a robust design, so devices intended for this market can have a lower mechanical strength, which makes them cheaper. However, the Protektel expert stresses one important detail:

“While our PROXAR® surge arresters, compliant with IEC 60099-4:2014 and IEEE C62.11-2020, are used for both substations and power line protection, strictly line arresters (TLA) in most cases do the mechanical strength suitable, to be mounted on supporting structures in substation applications or other system areas.”

Jacek Turkowski, Director of Marketing and Sales at Protektel

PROXAR® surge arresters vs. IEEE C62.11-2020

The main components of PROXAR® surge arresters have parameters that exceed the requirements of the IEEE C62.11-2020 standard. This is a result, among other things, of the use of high-quality varistors in the design of these devices. This is confirmed by the results of tests carried out per the latest version of the EN 60099-4 standard.

Protektel's surge arresters can also be used for in-line protection, which is widely used in the Americas. In addition, thanks to their robust mechanical design, makes them suitable for the protection of substations.

In Europe, we say: PROXAR® Unlimited trust, because when you work with us, you can count not only on high-quality surge arresters, but also on the expert advice and knowledge of our experts.